Connectors 101: Understanding Board to Board Connector

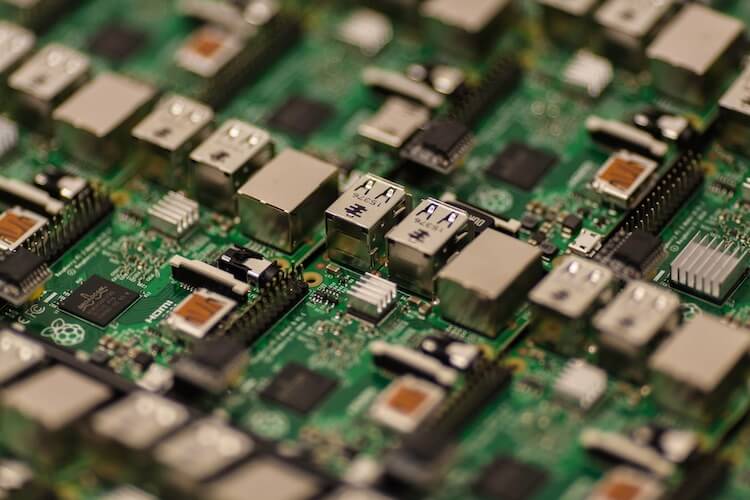

When it comes to connecting PCBs (Printed Circuits Boards), board to board connectors are used. They connect PCBs without making use of wires.

This type of connector is generally made of plastic and metal straps. Board to board connectors are comprised of two linking parts; the first part has pins and is attached to a single PCB, whilst the other part containing receptacles is mounted to another printed circuit board. The PCBs are then connected by mounting two sides of the connector.

The height of some board parts varies, hence they need more spaces between connected PCBs to facilitate the spaces.

For you to better understand what board to board connectors are, then keep on reading.

Technological Interface

Board to board are manufactured with the use of surface mount or through-hole technological interface. These mounting applications have various benefits and uses.

- Surface Mount — this type of connector is mounted on the top of a printed circuit board, directly. It has short headpins that don’t go past the board. Surface mount components can be produced to be smaller and are less expensive to purchase. However, it is not applicable to standard circuit boards; they have weaker solder connections too than through-hole.

- Through-hole — these connectors use contacts to connect and are installed through drilled holes in the printed circuit board. The contacts are also soldered on the opposite part of the board in order to complete power connection. Also, through-hole connector is extensively used when it comes to prototyping because of circuit board compatibility.

Buyer Specifications

Customers buying board to board connectors may specify details regarding the product’s features, types, and contacts. For this type of connectors to maximize their potential in terms of operation, most of these specifications are determined properly. This is also similar when ordering customized commercial led strip lights wherein specifications are given beforehand.

Header Requirement

The board’s header serves as a determinant for you to know what type of board to board connectors you are using, either a mounting plate or a plastic base. There are two types of headers — box headers and pin headers. Box headers entirely encapsulate their contacts, while a pin header exposes its contacts.

Board to board connectors have two gender settings — male connectors and female connectors. Male connectors are referred as plugs with protrusions that fit into female connectors which is referred as receptacle.

Connector Contacts

Board to board connectors may feature pins organized in one or two columns. If a contact has a larger pitch, it means the connection density is lower (less connections per area). The connector’s pitch can affect the arcing.his happens when two insulators are situated closely causing an interference. Typical pitches are under 0.5 mm to 5 mm.

Since contacts are conductive components meaning they transmit electrical energy, they can be in metal plated form. This is to improve the connection performance. Typical metals include silver, nickel, copper, and gold. Contacts in gold plated form are more expensive, but they provide the most optimum electrical connection than the others.

Special Features

Below are two special features of board to board connectors.

- Environmental — this explains the extent to which the equipment is protected against liquids, dangerous chemicals, and other external factors. Cable manufacturers may offer hermetically covered connectors that are chemical, oil, or waterproof. There are some connectors that are manufactured specifically for cryogenic purposes.

- Connection — this is the connection method of the product itself. Connectors with lock system prevent unwanted disconnection. Connectors with quick connect feature can be quickly connected and disconnected, oftentimes using a contact in a twist and seat scheme.

Board to Board Plating and Contact Material

Plating and contact material of board to board connectors are manufactured using superior quality materials and copper alloy. The materials are budget-friendly and simple to manufacture and produced with decent electrical characteristics. Layers of metal plating are added within the internal core of the connector to improve the following:

- Electrical performance

- Soldering ability

- Wearproof

- Corrosion resistance

- Protection against intense temperatures

- Overall appearance

Contacts are also metal-plated with nickel to:

- Withstand material migration between the completed plating and foundation material.

- Provide corrosion resistance and tear.

Conclusion

Board to board connectors is one of the important components for various cable-related applications. It is important to understand how these connectors work toward a certain application. Keep in mind that this type may not be applicable to all customer specifications. Apart from its great features, board to board connectors are less expensive and is quicker to install. To further understand if this connector type is compatible with your project, you may ask your connector manufacturer for further details.

References: